OPTIONAL DEVICES:

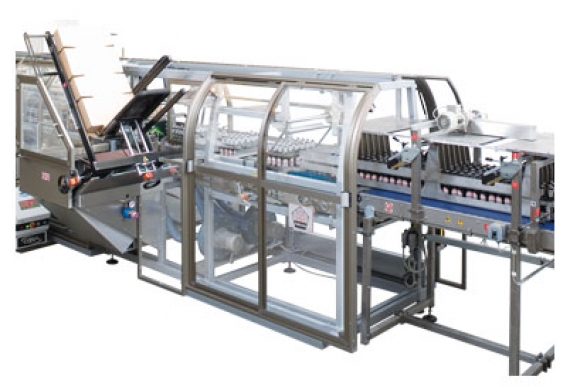

“BM-BELT™" System

The exclusive BM – BELT patented system allows packing products in film only by using a motor positioned conveyor belt, which automatically excludes the tray/carton transport chains.

“AUTOMATIC DOUBLE REEL” system

It is possible to have as an optional upgrade the revolutionary automatic reel change over system. The film reel change over is made at production speed and with no film welding.